The rule of induction melting is that a high voltage electrical source from

an essential coil impels a low voltage, high current in the metal or auxiliary coil.

Induction heating is just a system for exchanging heat vitality . We are in the

period of progress; huge changes occur in industry and business.

The individuals who consider

change to be opportunity survive the worldwide rivalry and those consider it to

be an issue will die. Foundry is a testing business. In today's foundry, profitability

improvement and moving forward vitality proficiency are two key parts of accomplishment

for the Indian foundry industry. Efficiency could be seen as huge amounts of throwing

created per foundry or basically huge amounts of castings created per man-hour,

either ways we are path underneath the world's normal; actually our efficiency

is one fourth at the point when contrasted and German foundries.

The Indian foundry industry has

developed jumps ahead in the previous decade or two, yet Worldwide rivalry has

developed at just as quick pace. The generation from our foundries practically

touched 10 million tons a year ago.

Casting industry :

It

can be seen from chart that aggregate generation developed from 4.038 million

metric tons (mt) in 2003-04 to 9.344 million mt in 2013-14, this compares to a

compound yearly development rate (CAGR) of 8.75 for each penny.

China has

additionally developed at CAGR of 8.88 per penny amid the same period, though the

world's casting generation developed from 73.554 million mt in 2003-04 to

100.834 million mt in 2013-14. This compares to a CAGR of 3.20 for each penny

just. The high development in India and China, at the point when contrasted

with the world, is on account of amid this period casting industry seen moving

of casting creation from Europe to Asia. Europe saw a negative development with

CAGR of - 0.37 for every penny amid this period.

Melting :

Melting is the heart of the

foundry industry. A melting furnace determines its heat from strong fills

(coke), normal gas, power, or different wellsprings of vitality. Furnaces shift

in outline, geometry, limit profitability (melting rates), materials of-development,

what's more, method of operation (clump or ceaseless). Quantities of

alternatives are accessible for melting furnace. Aside from the furnaces

specified in Table 1, there are various imaginative melting advancements under

examination and improvement. Some of these are: Electron pillar melting,

drenching heater, infrared heater, microwave melting, plasma heating what's

more, sun based furnace.

If there should arise an

occurrence of ferrous castings, prevalent offer is of cast iron, for melting

cast iron two most normal furnaces utilized as a part of the Indian foundry

industry significantly produces dark iron castings which compares to 67 for

each penny of aggregate casting creation. The remaining are steel casting 12

for every penny, SG iron and non-ferrous 10 for each penny each. They gives

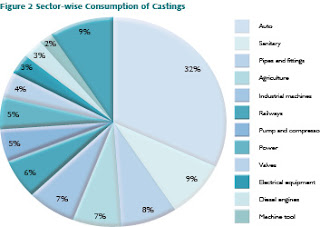

castings to different divisions, car is major, right around one third of

aggregate casting creation. Indian foundry are dome furnace utilizing coke as

fuel and induction furnace utilizing power. On the premise of essential

vitality utilization, if induction furnace and vault are looked at, the weight

turns totally for dome. Yet, the benefits of a cauldron furnace over vault

furnace incorporate adaptability to the extent generation of distinctive

composites are worried, specifically to melt pliable iron.

Induction furnace

In 1966 German creator Karl-Heinz

Brokmeier composed: "Induction melting is in a condition of quick

advancement." All through the 60s and 70s a sensational development of

mains recurrence induction furnace was seen over the world. Later in the 80s

with presentation of medium recurrence induction furnace, the ball-game changed

completely. This was beginning of a blast of induction furnace in foundries.

Our role :

No matter which metal you melt,

cast or forge or any process, we stead fast manufacturers proud to provide you

world best solutions, whether it is melting or heating solution.

Stead fast engineers is leading Induction

furnace manufacturers in India , melting solution, heating solution and

much more . Visit our Site : http://www.steadfastengg.com/

No comments:

Post a Comment